Product

Pressure Die Casting Process

Additional information

JYNDA METALCASTING

Production Description

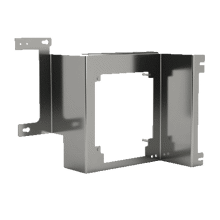

Pressure Die Casting Spare Parts Customized Casting

Cylinder Kit Die Casting Engine Hardware

- Material: Aluminum (such as A380, ADC12, A360, ADC10,etc); Magnesium ; Zinc, etc

- Process of Die Casting: Raw Material →Cutting →Die Casting→Raw blanks → Trimming → Deburring →CNC machining(Precision machining) →Surface treatment → Final Inspection→ Package → Shipping & Delivery

- Our Advantages:

a. Experienced Factory with professional technical support and sales team with quick response

b. The ability of re-design components for cost reduction

c. Strict quality control process

d. Especially specialized in Low volume even 1pcs for high mix components .

-

Our Machines:

a. Die Casting Machines from 160t to 800t toal 8x.

b. CNC machines including milling, turing and lathe machines total 44x.

c. Painting Line=power +wet painting toal 4x.

- Certificate: ISO9001 is available

JYNDA METALCASTING

Production & Testing Workshop

Introducing our comprehensive testing and packaging solutions! At our company, we prioritize quality assurance by implementing rigorous testing procedures to ensure the reliability and performance of our products. Our advanced testing equipment and skilled technicians conduct thorough inspections, guaranteeing that each item meets the highest standards. Additionally, we emphasize the importance of secure packaging to protect your products during shipping and storage. With our commitment to quality control and meticulous packaging, we deliver excellence from production to delivery.

-5-300x300.png)

-4-300x300.png)